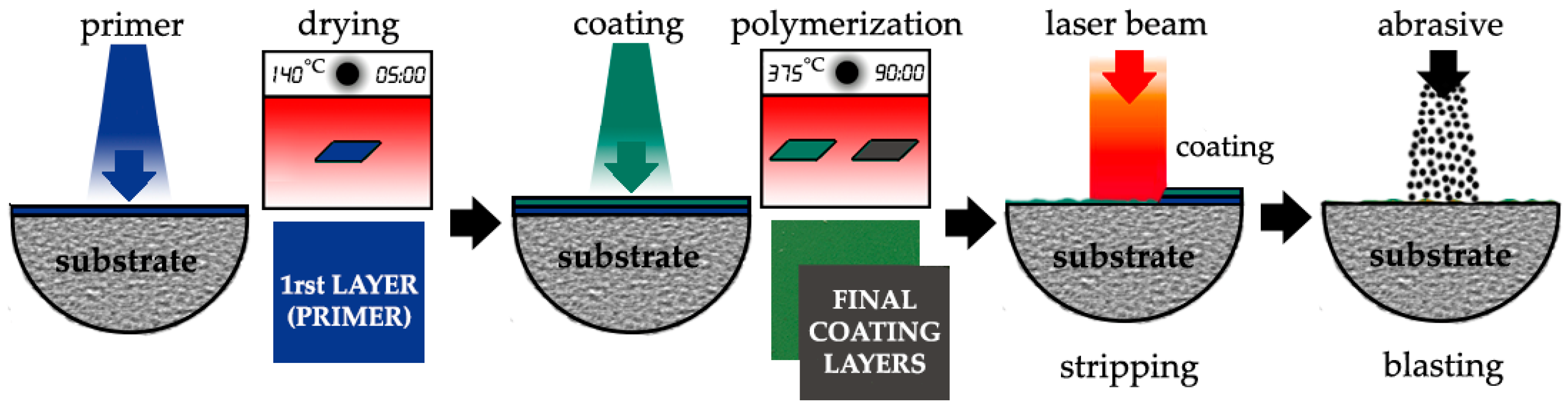

In the automobile and aerospace industry it is sometimes necessary to remove the top layer of paint while maintaining the primer.

Naval application of laser ablation paint removal technology.

This is often the case when the top weathered coatings on vehicles need to be thoroughly removed before the application of a new.

The radome was affixed to a device that rotated as the laser beam ablated the paint from the surface.

Both private sector repair yards and government naval shipyards desire a safer more efficient and environmentally friendly method of paint removal.

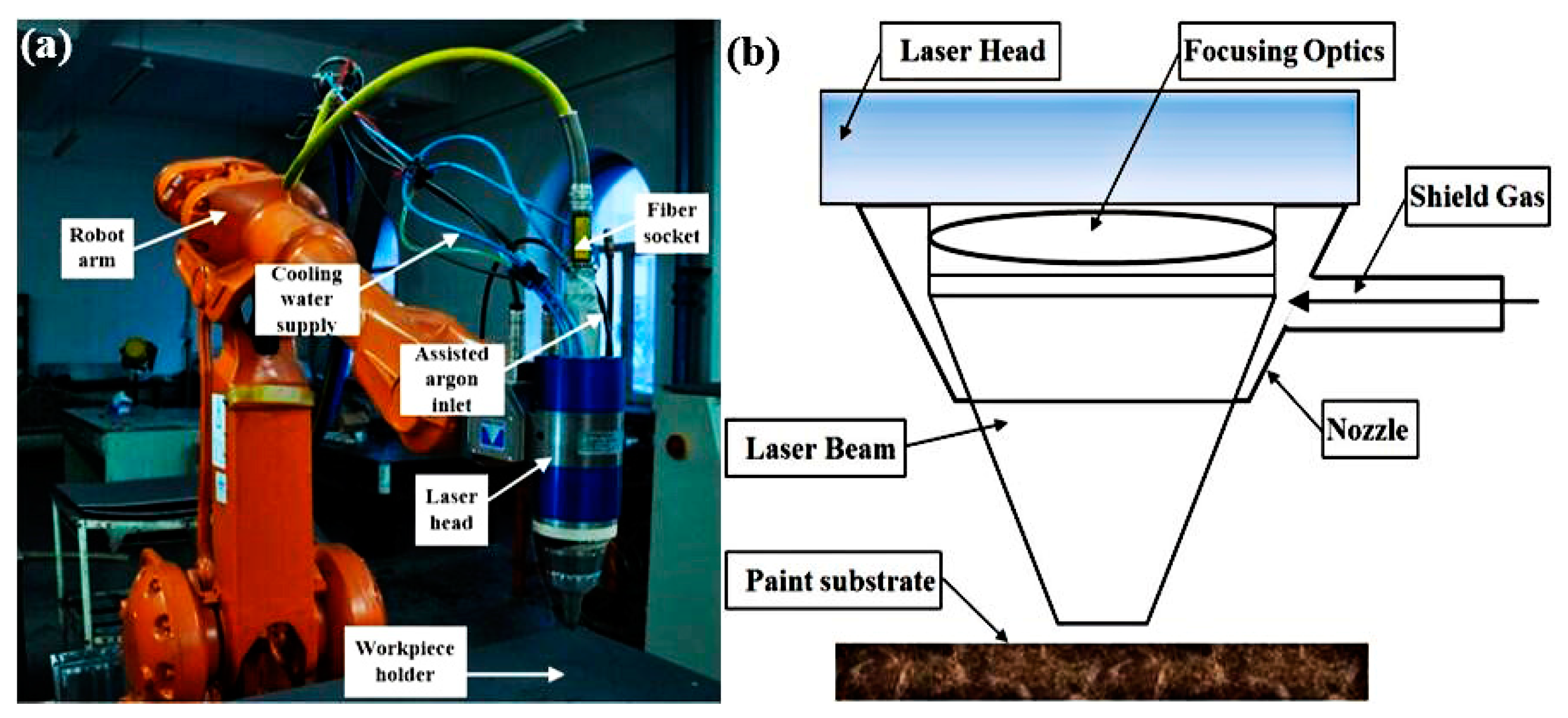

The laser beam is pulsed onto the part with a precise energy density.

The company used this technology until about 2000 when it was replaced with an nd yag laser from northrop grumman s cutting edge optronics in st.

Laser removal of protective coatings from naval vessels is a promising alternative to traditional paint stripping methods such as grit blasting chemical paint stripping needle grinding etc.

Over the last few decades abrasive blasting was the most widely used paint stripping method used for large area marine structures though smaller repairs may be performed using various handheld tools.

Laser ablation produces significantly less waste than do other stripping processes.

Selective paint removal represents one of the many applications of laser cleaning.

The lasertronics laser ablation system dramatically reduces and simplifies management of the waste products generated by stripping.

Proposed solution the objective of the proposed work is to develop a laser ablation paint removal technology and process with a comparable removal rate and reduced overall cost to current methods that is also environmentally friendly and operator safe and friendly.

It s also known as laser coating removal and de coating.

With a predictive three times more efficient removal rate markedly improved worker safety and reduction in hazardous waste streams the business case is clear.

As the paint is vaporized the.

The co 2 laser generated a 0 5 in.

Laser ablation offers tremendous potential as a game changing technology to improve the efficiency of naval maintenance related to preservation.

It does this in two ways.

During coating removal the surface temperature of the radome never exceeded 170 f.

Laser paint removal laser paint removal is a process through which a paint layer is removed from a surface without damaging the substrate.

Laser demand when lasertronics launched its first paint stripping system in the mid 1990s it did so with a co 2 laser.

Jim russell lasertronics director of business development said the nd yag s flexible fiber optic beam.

In contrast closed loop laser technology has proven successful in demanding applications including stripping on helicopter rotor blades removal of specialty coatings on military aircraft removal of paint corrosion products on commercial aircraft and nuclear decontamination.